Description

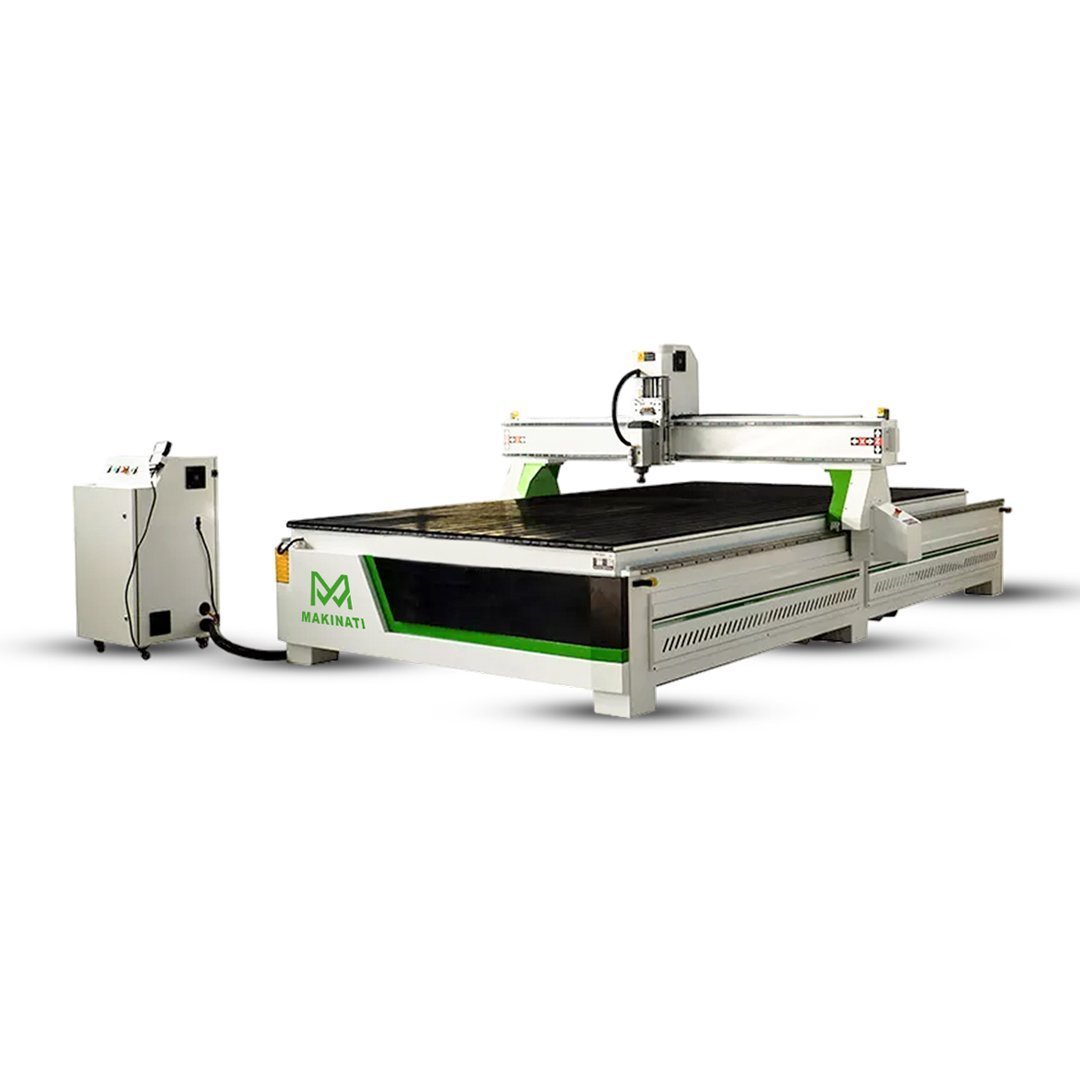

CNC ROUTER 2160

CNC router 2160 are multi-tasking machine used in various industries in saudi arabia because of that Makinati KSA Company offering cnc router in jeddah, riyadh, makkah, Madina and in all cities of saudi arabia:

CNC Router in jeddah and Riyadh for Woodworking:

Makinati is offering CNC Router in jeddah and other cities of saudi arabia which you can use for Cutting, shaping, and engraving wood for furniture, cabinetry, and decorative items. CNC Router reduce manpower and increase production. CNC Router work efficiently and give you outclass results.

Plastics and Composites cnc router in jeddah 2160:

We Provide CNC Router 2160 which can use for Cutting, engraving and forming parts for industrial products, packaging, and prototyping.

Sign Making:

Now our customer’s are using cnc router 2160 for Engraving and cutting materials like acrylic, plastic, and wood for signs and displays.

Arts and Crafts:

Best cutting and engraving , wood, custom jewelry, and other intricate designs.

wood cutting machine:

When you talk about the wood cutting with high speed and accurate engraving and cutting so first name come in the mind is cnc router. Makinati ksa company is offering best quality with high quality specification’s for its customer not only in jeddah but other cities of the saudi arabia as well.

Main Parts of the CNC Router Machine:

| 1 | Spindle | Original 6.0KW HSD Air Cooling Spindle |

| 2 | Control System | OriginalA11 DSP Control System |

| 3 | Driving Motors and

Drivers |

XAxis: 1500W Leadshine Servo Motor+ Driver |

| YAxis: 1500W Leadshine Servo Motor+ Driver | ||

| ZAxis: 1500W Leadshine Servo Motor+ Driver+Brake | ||

| 4 | Control System | Original 4000E Controller |

| 5 | Ball Screw | High Precision Taiwan Designed Ball Screw |

| 6 | Rails | High Precision HIWIN Square Rails |

| 7 | Blocks | High Precision HIWIN Blocks |

| 8 | Rack and Opinion | HighPrecision Taiwan Designed Helical Tooth |

| 9 | Machine Structure | HeavyDutyStructure and Strong Structure (Double Strengthened

Structure) |

| 10 | Spindle quantity | One Spindle |

| 11 | WorkingTable | T-slotandVacuumCombined Working Table |

| 12 | Electronics | Original France Schneider Brands |

| 13 | Tool Sensor | Included |

| 14 | DustCollector | IPad computer licensed software |

Parameter:

| 1 | Max. engraving area | 2100*6000*300mm |

| 2 | Acceptable material

thickness |

300mm |

| 3 | Working table | T-slotandVacuumCombined Working Table |

| 4 | Working table size | 2100mm*6000mm |

| 5 | Processing resolution | ±0.1mm |

| 6 | Re positioning resolution | ±0.02mm |

| 7 | Spindle motor | Original 6.0KW HSD Air Cooling Spindle |

| 8 | Spindle rotating speed | 18000rpm |

| 9 | Transmitting system | XY axis Rack and Opinion+ Square guide; Z axis ball screw+ Square

guide |

| 10 | Driving motor | 1500W Leadshine Servo Motor+ Driver |

| 11 | Power consumption | 2.0KW(Without Spindle) |

| 12 | Empty Traveling Speed | ≥40000mm/min |

| 13 | Processing Speed | ≥20000mm/min |

| 14 | Spindle Quantity | 1 spindle |

| 15 | Control system | A11 DSP Control System (Original Brand) |

| 16 | Format | G code |

| 17 | Voltage | 3 Phase 380V, 50HZ |

| 18 | Surroundings | Temperature: 0-45℃; humidity:30%-75% |

| 19 | Net Weight | 3350KG |

| 20 | Packing Size | 6550mm*2290mm*1900mm |

CNC Router and it’s Key Features:

In our CNC router 2160, you might expect the following features same as mention below :

- Cutting Area of Router: The model number may indicate the size of the cutting area of the machine. A larger number often ability to implies a larger cutting area, which is suitable for bigger projects for the companie’s.

- Spindle Power of Router: CNC Router Higher spindle power (kilowatts or measured in horsepower) is high speed router and allows for cutting materials and achieving faster cutting speeds because of its efficient spindle power.

- Axes Movement: Most CNC routers 2160 are 3-axis (X, Y, Z), but higher-end models can be 4-axis or 5-axis, allowing for more complex cuts and 3D machining which are more efficient comparetivly non ATC router.

- Router Precision and Accuracy: if you Look for high precision and low tolerance for detailed work so cnc router 2160 is best for your company.

- Software Compatibility for cnc router: there are some specific software for the cnc router so recommended and compatible with popular CAD/CAM software for easy design and manufacturing integration.

- Build Quality of cnc router: A structure frame is high-quality and other components are durable and reliable.

- Ease of Use Router: Makinati ksa provide cnc router which are User-friendly interfaces and software can make operation and programming easier than ever.

CNC Router in Jeddah and other cities Specific Model Details 2160

If you want to buy cnc router 2160 so makinati ksa is offering in low price’s wiht specific model from a particular manufacturer, check out the manufacturer’s website www.makinatiksa.com